Greener shipping industry

For years, the environment has been on the agenda of world leaders, environmental groups and ordinary citizens. The future of our planet and our children has all the attention. The goals and measures of governments focus both on the reduction of nitrogen and particulate matter and the reduction of CO2 emissions.

One of the sub-goals is to achieve a ( nearly) emission-free and climate-neutral inland shipping sector by 2050 with as an intermediate step:

– By 2030 to reduce CO2 emissions from the Dutch inland shipping fleet by 40% to 50% compared to 2015.

– By 2035, reducing the emission of environmentally hazardous substances from inland shipping by 35% to 50% compared to 2015.

To achieve these goals, one of the efforts is to transition from gasoil to LNG as a fuel.

LNG, ‘Liquefied Natural Gas, is gas derived from vegetable residues or manure. LNG is liquid at a temperature of -162°C. In its liquid state, its volume is about 600 times smaller than in gaseous form. This allows you to store and transport LNG more efficiently, contributing to sustainability.

In addition to a price advantage, this transition for the shipping industry also has several environmental benefits, such as a direct reduction at the source of emissions NOx, SOx and CO2 which improves our air quality and complies with emissions regulations.

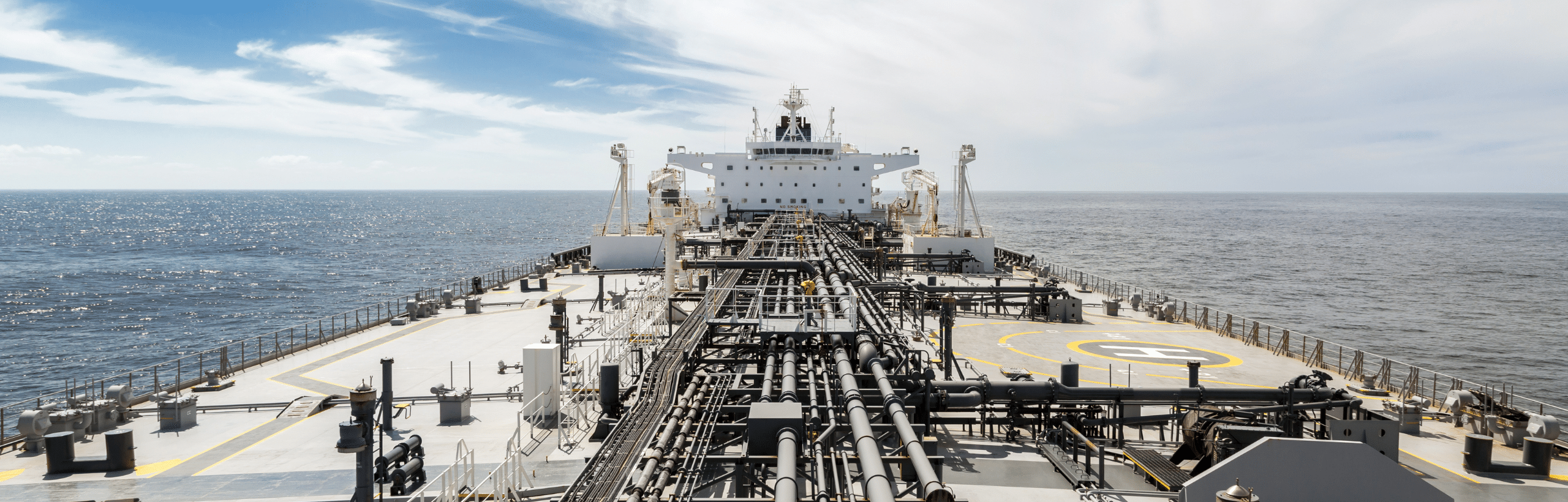

The transport of LNG from the source to the users is mostly by seagoing and inland ships. Loading to the ship, storage on board and transport ashore is done using stainless steel piping. Naturally, the safety requirements here are high. Depending on the country, shipping company and/or end user, it is determined which product and inspection standards the materials must meet.

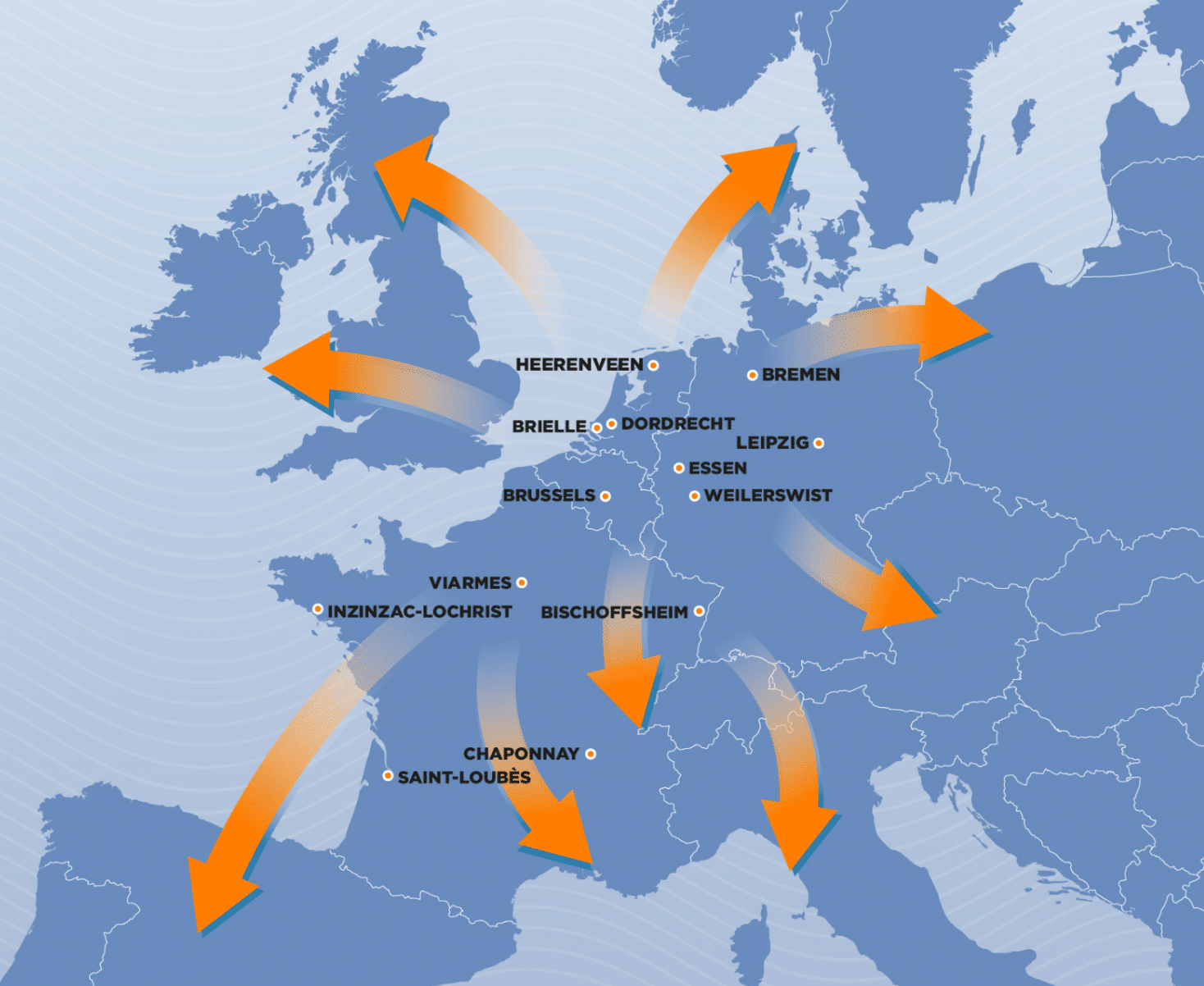

In the Netherlands, Belgium and Germany, piping that complies with:

– API (American Petroleum Institute)

– ASTM (American Society of Testing Materials)

– EN standard (Euro standard)

Naturally, we at Arcus have a large stock of stainless steel and CS piping that meets the above standards, spread across various locations.

Piping on board ships, in addition to the requirements laid down in these standards, is often subjected to additional examination at the client’s request. This process is popularly known as “upgrading.”

The additional tests (e.g., bending test, tensile test, kerf test) are performed in an independent laboratory and whitnessed by a Notified Body, such as: Lloyds Register of Shipping, Bureau Veritas, Det Norske Veritas and Rina.

Taking care of your worries is a top priority at Arcus, which is why we are happy to take care of this upgrade process for you.

If after reading this blog you still have questions about standards, certificates or our products, please feel free to contact me.