The best steel solutions you find at Arcus

-

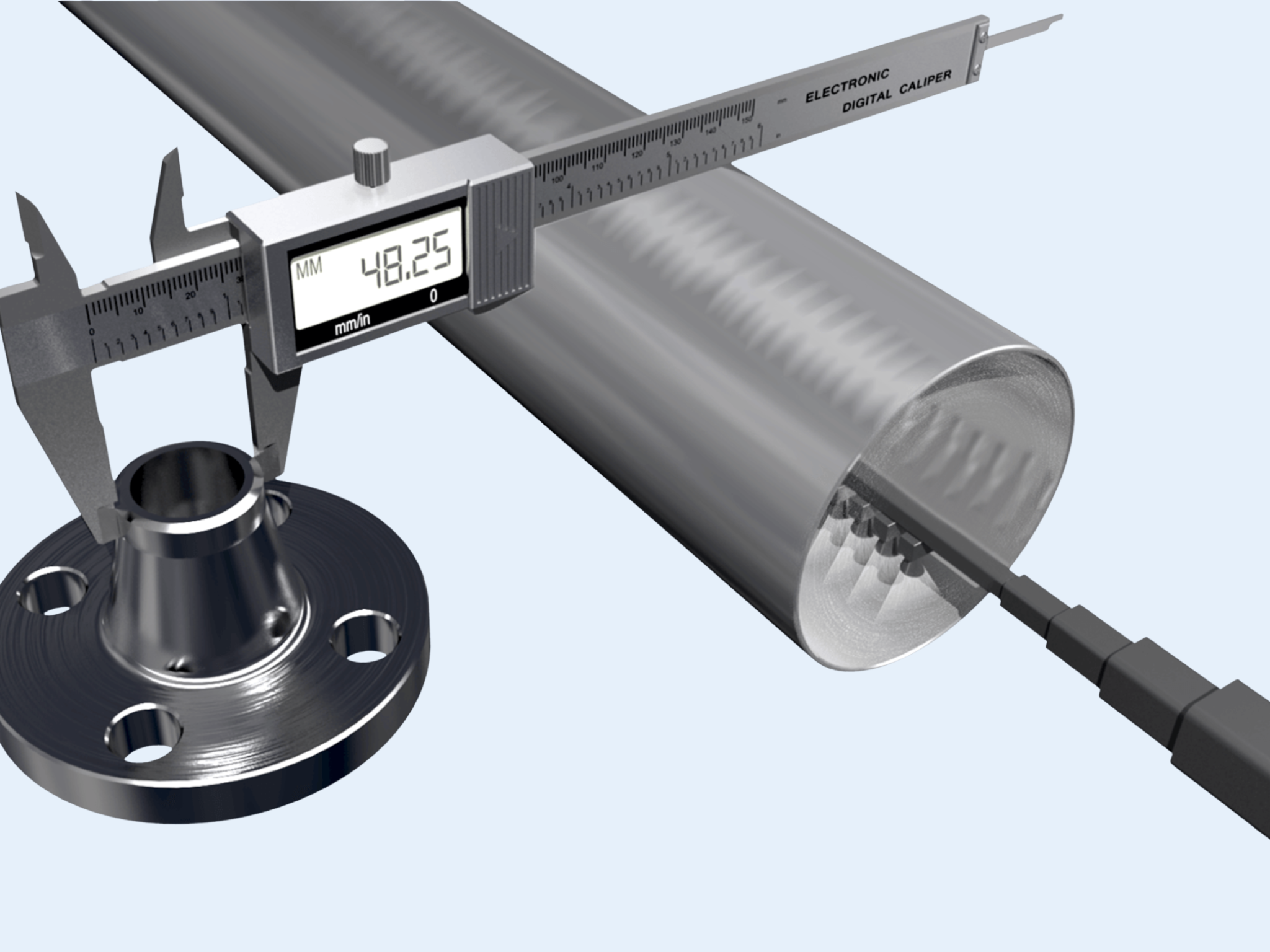

Pipes

-

Flanges

-

Fittings

-

Industrial Supplies

-

Machining & Pickling

Our mission

Always doing the best for our customers, that's what we stand for.

We are the supplier in the field of stainless steel pipes and components for industrial applications. Always doing the best for our customer, that is what we stand for.

Why choose Arcus?

The stainless steel market is complex and dynamic. Knowledge about this market and products is therefore essential. As is the ability to switch quickly and flexibly. We have that knowledge and vigorous.

Prompt a complete quotation

Fast delivery

within Europe

Your own

one-stop shop

Multiple

stock locations

Arcus Group

“At Arcus, we join forces to exceed customer expectations. This is our purpose. By sharing knowledge and combining our expertise, we deliver solutions that make a real impact.”

Discover all our entities